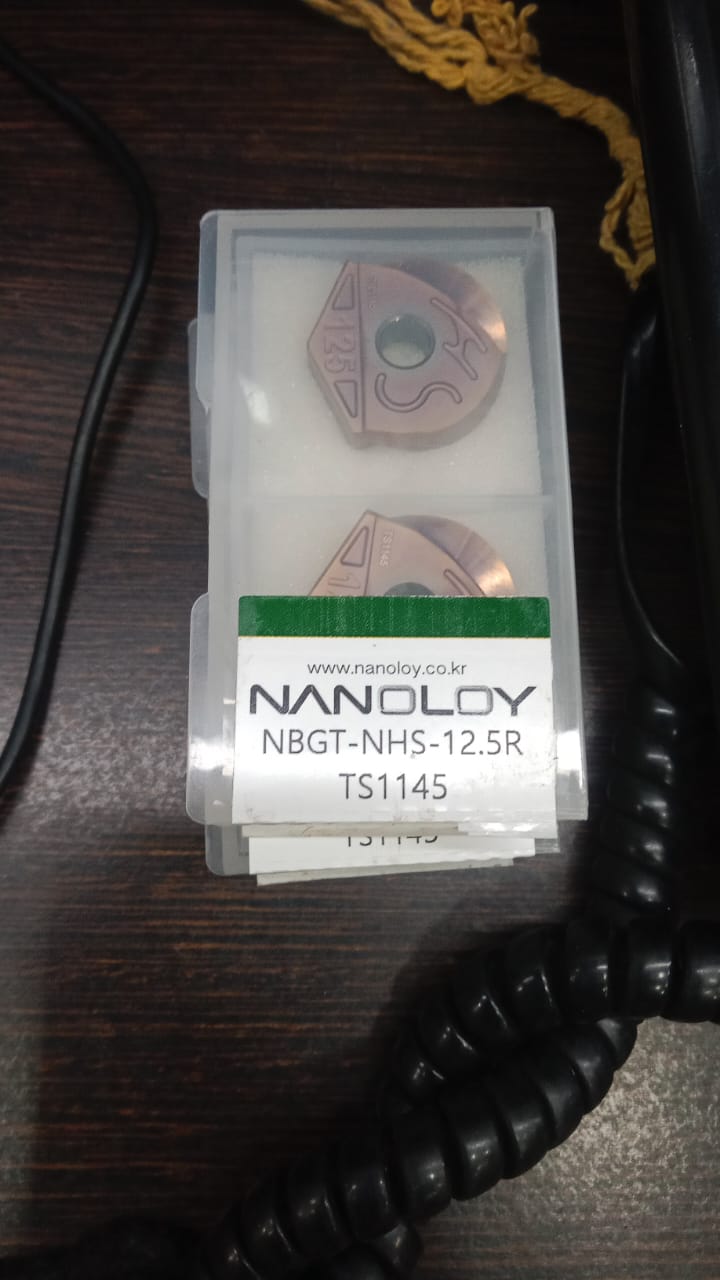

Nanoloy Indexable Insert Dealer In Delhi Nanoloy Indexable Insert Key Features 1. Advanced nanotechnology coating: Enhances wear resistance and reduces friction. 2. Tungsten carbide substrate: Provides exceptional hardness and toughness. 3. Indexable design: Allows for easy insert replacement and reduces downtime. 4. High-precision geometry: Ensures accurate and precise cutting. Benefits 1. Improved tool life: Withstands heavy use and reduces the need for frequent replacement. 2. Enhanced productivity: Increases machining efficiency and reduces cycle times. 3. Improved surface finish: Produces high-quality surface finishes and reduces the need for secondary operations. 4. Cost-effective: Reduces tooling costs and minimizes waste. Applications 1. High-volume machining: Ideal for high-production environments and mass production. 2. Precision machining: Suitable for applications requiring high-precision cuts and tight tolerances. 3. Difficult-to-machine materials: Effective for machining hard, abrasive, or exotic materials.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry